In part one of this series, we discussed how the deli department is a vital organ of each co-op that has one. Columinate consultant Dana Tomlin says that while it is possible for a deli to operate in chaos, and many do, the long-term health of your living, breathing, prepared foods department depends on systems. Knowing whether those systems are operating as they should requires that the general manager understands them and has buy-in and support for those systems from the entire store.

while it is possible for a deli to operate in chaos, and many do, the long-term health of your living, breathing, prepared foods department depends on systems. Knowing whether those systems are operating as they should requires that the general manager understands them and has buy-in and support for those systems from the entire store.

Tomlin’s on-site evaluation of the deli department and the existing conditions helps to set a baseline for what is working and what systems need to be adjusted or created. Her experience both in kitchens and as a general manager (GM) herself gives her the ability to translate what she sees to what the GM needs to learn to see.

“It can be small things that tell you big things. Is silverware stocked? If not, that means the deli (staff) hasn’t come out to refresh the salad bar in a while,” Tomlin explains.

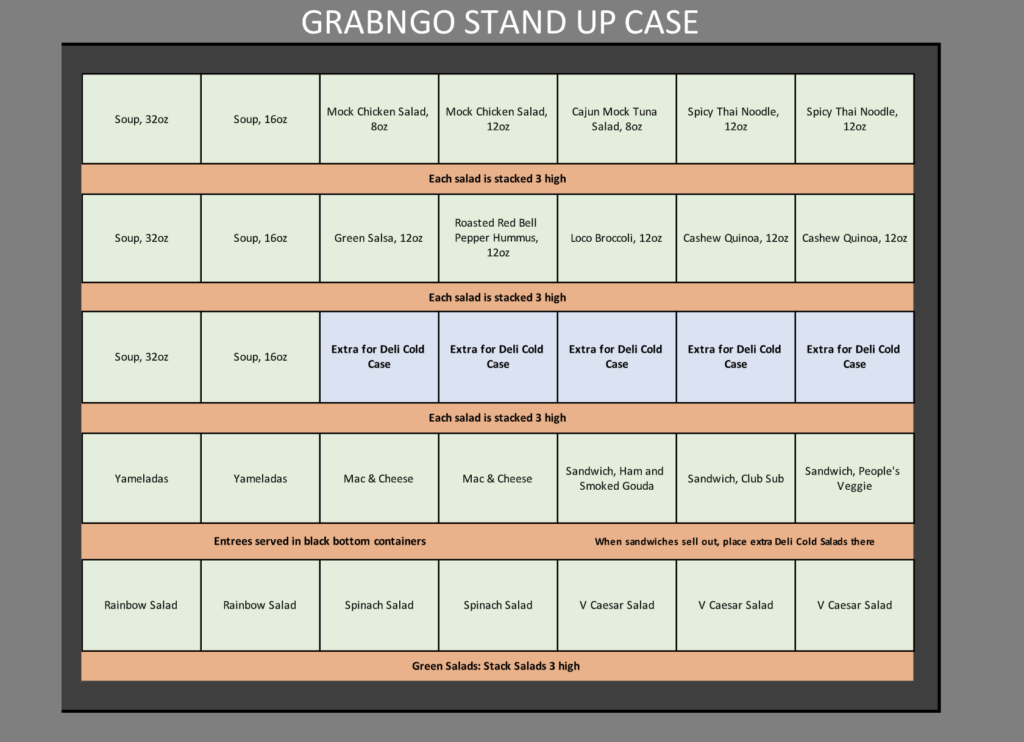

When Tomlin puts deli systems into place—such as a full grab-and-go case planogram, or the production schedule for a well-stocked salad bar—those systems determine how things will be done and who is responsible for doing them. Once those systems are created and staff is trained, the GM is also trained to understand what things should look like in front of the house and in the kitchen.

Having other managers throughout the store trained to keep an eye on the department during store-wide walks is an important piece to building the right culture. When the deli operates well and consistently has the product customers are looking for, the entire co-op benefits.

Production team planograms

Matt Sunderland is the director of prepared foods at River Valley Co-op and has worked closely with Tomlin on his co-op’s deli systems. Tomlin began her work with River Valley before Sunderland was hired there. “Before Dana was here, we had two stores with no systems and no continuity between menus and recipes. The two stores had the feeling of two totally separate deli departments. Dana brings a high level of leadership and expertise. She helped organize the production teams with planograms for service areas that lead to a production schedule and then can be used for staff scheduling and purchasing.”

An early covid-era trend saw a lot of people with experience in restaurants coming to work in grocery store kitchens for the first time. Sunderland has a restaurant background and benefited by learning from Tomlin. “I have a lot of years of experience in running kitchens, but not a deli in a store. Dana provides clear and direct systems training with ways to organize production. She also supported me in learning new software for recipe costing and ensured I used it fully along with navigating Catapult reports specific to deli. She helped in a hands-on fashion with pretty difficult systems.”

River Valley GM Rochelle Prunty has been integral to working with Tomlin and supporting the growth and systems in the deli. Sunderland has felt supported by his GM to help achieve the department’s goals, including investing in his own growth by allowing for ongoing engagement with Tomlin. Sunderland expanded on this: “GMs want to see results, and the investment in high-level training has proven beneficial to the bottom line of the prepared foods department. Training from the top down starts a trickle-down effect that will help develop a strong foundation to share knowledge and experience with all managers and staff. As a team, Dana and I have been able to produce margin gains, better shrink numbers, higher-quality and diverse menus, and cleaned-up recipes with a more organized kitchen team.”

Better department organization and consistency

Tomlin’s other current engagement has been with Ocean Beach People’s Co-op in San Diego, California. Their POS administrator, Kylie Oliver, spoke about the various changes Tomlin has helped to implement in Ocean Beach’s deli department and throughout the store. Details as small as properly setting up PLUs to comply with tax laws are a part of the work. Said Oliver, “California is very complicated with tax laws, and she’s done a lot of research to nail down taxation of various items. We’re creating a whole new set of PLUs and setting them up so similar items are grouped. We’d been running on PLUs that are 35 years old, and there was no consistency to the system. Building in consistency from that aspect is huge.”

Oliver described changes in the deli since they began working with Tomlin, including better organization and a clear vision of seasonal foods and seasonal menus. Communications, production schedules, and even signage in the department have improved since the engagement began. “She created a plan outline with visions for the future and who is involved. It had a step-by-step outline of the vision. This is how we’re going to get there. She put a timeline on each step, and who is in charge of each step. It’s all built around a lot of communication.”

Oliver shrewdly pointed out an affliction of most if not all co-ops when it comes to buy-in on a new direction for a store or a department. “Generally, in the co-op world, change is difficult. It’s easier to make changes that you’re comfortable with and staff are comfortable with. Who Dana is as a person makes it easier to accept that change. We’re being told by someone with a lot of experience who’s advising us.”

GMs rely on that buy-in at every level, from POS administrators to the head of the deli department, to understand and support changes. A track record of proven results and easy-to-follow systems built to lighten the overall workload and improve customer experience are crucial to earning that buy-in. Systems that surpass an individual staff member and become ingrained in the operations of the co-op are the kind that lead to long-term deli success—maintaining a strong and healthy organ.

Have more questions?

Get in touch with one of our consultants.